Keeping track of inventory is essential for any business, whether it’s a small retail store or a large warehouse. One of the most effective ways to ensure accuracy in your inventory management is by conducting regular physical inventory counts.

This involves physically counting the number of items you have in stock and comparing it to the number recorded in your inventory management system. To make this process easier, many businesses use physical inventory count sheets.

This article will explore the purpose of a physical inventory count, the process of conducting one, and how to sync the physical count with your inventory management system.

What Is a Physical Inventory Count?

A physical inventory count, also known as a stock count or stock take, is the process of physically counting the number of items you have in stock. It is a way to verify the accuracy of your inventory records and identify any discrepancies between the physical count and the recorded count in your inventory management system.

By conducting regular physical counts, you can ensure that your inventory records are up-to-date and accurate.

Purpose of a Physical Inventory Count

The main purpose of a physical inventory count is to ensure the accuracy of your inventory records. By comparing the physical count with the recorded count in your inventory management system, you can identify any discrepancies and take appropriate action to correct them. This can help prevent stockouts, overstocking, and other inventory-related issues that can negatively impact your business.

In addition to verifying the accuracy of your inventory records, a physical inventory count can also help you identify any shrinkage or loss of inventory. By comparing the physical count with the recorded count, you can determine if any items are missing or if any discrepancies need to be investigated.

Physical Inventory Counting Process

The process of conducting a physical inventory count can vary depending on the size and nature of your business. However, some common steps can help guide you through the process:

1. Plan and Prepare

Before conducting a physical inventory count, it’s important to plan and prepare. This includes determining the best time to conduct the count, ensuring you have the necessary resources (such as staff and equipment), and communicating the count to your team.

2. Organize and Sort

Before counting, it’s important to organize and sort your inventory. This can involve categorizing items, grouping them by location or SKU, and ensuring they are easily accessible for counting.

3. Count the Items

Once you have organized your inventory, it’s time to start counting. This can be done manually by physically counting each item, or you can use barcode scanners or other automated tools to streamline the process.

4. Record the Count

As you count each item, it’s important to record the count accurately. This can be done on a physical inventory count sheet or directly into your inventory management system. Make sure to label each item or location as you count to avoid confusion.

5. Reconcile and Investigate Discrepancies

After completing the physical count, it’s time to compare the recorded count with the physical count. If there are any discrepancies, it’s important to investigate and reconcile them. This can involve conducting a recount, checking for misplaced items, or investigating any other possible reasons for the discrepancies.

6. Update Inventory Records

Once you have reconciled any discrepancies, it’s important to update your inventory records to reflect the accurate count. This can involve adjusting the quantities in your inventory management system and ensuring that the physical count matches the recorded count.

How Do You Perform a Physical Inventory Count?

Performing a physical inventory count requires careful planning and execution. Here are some tips to help you conduct a successful physical inventory count:

1. Schedule the Count

Choose a time when your business is less busy to conduct the physical inventory count. This can help minimize disruptions and ensure accuracy.

2. Communicate with Your Team

Inform your team about the upcoming physical inventory count and explain the importance of accuracy. Provide them with any necessary training or instructions to ensure they understand the process.

3. Use Physical Inventory Count Sheets

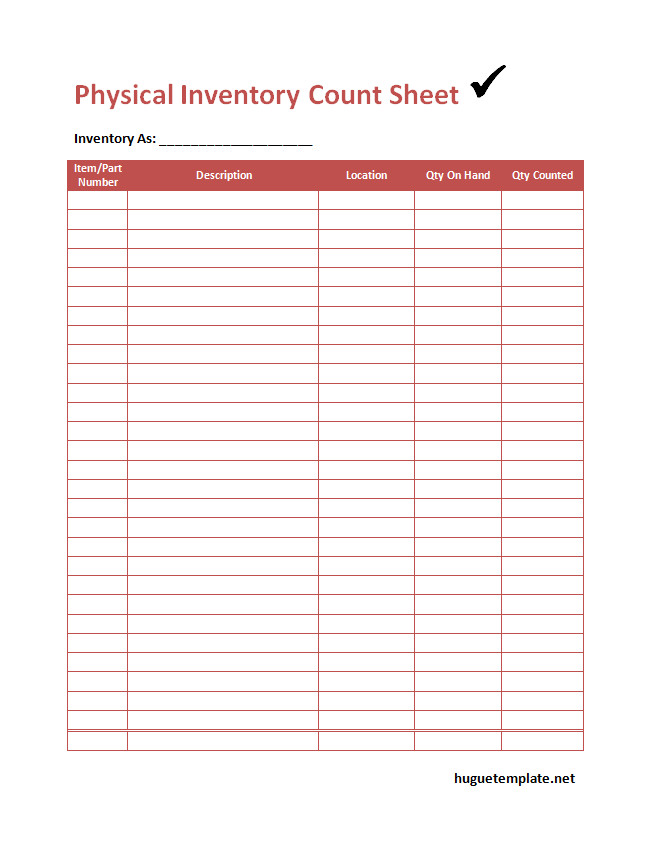

physical inventory count sheets can make the counting process easier and more organized. These sheets typically include sections for item descriptions, locations, and quantity counts. You can find count sheets online or create your customized sheets.

4. Assign Responsibilities

Assign specific responsibilities to team members during the physical inventory count. This can include counting specific areas or categories of items, recording counts, or reconciling discrepancies.

5. Ensure Adequate Lighting and Equipment

Make sure the counting area is well-lit and that team members have access to any necessary equipment, such as barcode scanners or calculators.

6. Conduct Regular Spot Checks

In addition to the annual or periodic physical inventory count, consider conducting regular spot checks throughout the year. This can help identify any discrepancies or issues early on and prevent them from becoming major problems.

7. Use Technology to Streamline the Process

Consider using inventory management software or barcode scanners to streamline the physical inventory counting process. These tools can help automate data entry and reduce the chances of human error.

8. Analyze the Results

Once the physical inventory count is complete, take the time to analyze the results. Look for any trends or patterns in discrepancies and identify areas where improvements can be made.

9. Implement Corrective Actions

If any discrepancies or issues are identified during the physical inventory count, take appropriate corrective actions. This can involve adjusting inventory levels, investigating the root causes of discrepancies, or implementing new inventory management processes.

10. Repeat Regularly

To maintain accuracy in your inventory management, it’s important to repeat the physical inventory count regularly. The frequency will depend on the nature of your business, but conducting an annual or quarterly count is a good starting point.

Free Physical Inventory Count Sheet Template!

A physical inventory count sheet can be a valuable tool in ensuring the accuracy of your inventory records. By conducting regular physical counts and syncing the physical count with your inventory management system, you can minimize errors, prevent stockouts, and improve overall inventory management.

Optimize your inventory management with our free physical inventory count sheet template!

Perfect for businesses of all sizes, this easy-to-use tool will help you maintain control over your inventory and enhance your operational efficiency.

Keep your stock organized and up-to-date with ease!

Physical Inventory Count Sheet Template – Word

I am Huguette Prudence, the writer and curator of this website. With a profound passion for writing and reading, I strive to create insightful and engaging content. My background includes managing a small online shop and overseeing a business website, experiences that have honed my skills and broadened my understanding of effective online communication. Thank you for visiting Huguetemplate.net, where I aim to share knowledge and inspiration through carefully crafted content.